Industry Applications

Subzero Engineering’s Simplex modular clean rooms were developed with custom applications in mind. The possibilities are endless. Whatever the unique requirement, our team brings industry expertise and a proactive approach to solving even the most difficult isolation challenges.

-

Portable Cleanroom Solutions Across Critical Environments

Portable Cleanroom Solutions Across Critical Environments

From biotech research to aerospace manufacturing, our modular clean room systems provide contamination control for diverse applications requiring flexibility, compliance, and rapid deployment.

-

Biotech R&D Labs

Biotech R&D Labs

Prefab clean rooms for cell culture work, genetic research, and prototype development. Modular systems adapt as research priorities shift, providing ISO Class 5-8 environments without permanent facility modifications.

-

E-Liquid & Vape Production

E-Liquid & Vape Production

FDA-compliant mobile clean room environments for e-cigarette and vaping products. Our instant cleanroom solutions meet current regulatory requirements while allowing production scaling and facility changes.

-

Aerospace Component Assembly

Aerospace Component Assembly

Portable cleanrooms for satellite components, avionics assembly, and precision manufacturing. Mobile systems accommodate project-based work and varying contamination control requirements.

-

Temporary Hazmat Isolation Rooms

Temporary Hazmat Isolation Rooms

Emergency containment using modular clean room technology for hazardous material handling, decontamination procedures, and environmental remediation. Systems deploy quickly for critical response situations.

-

Medical Device Packaging

Medical Device Packaging

Prefabricated clean room environments for sterile packaging that can be established in existing facilities without major renovations. Meet FDA and ISO requirements while maintaining operational flexibility.

Mobile Clean Room vs. Permanent Cleanrooms: Performance Comparison

| Feature | Mobile Cleanrooms | Permanent Cleanrooms |

| Install Time | 3-5 Days | 6-12 Weeks |

| Reconfigurability | Complete Flexibility | Limited Modifications |

| Compliance | Full ISO Classifications | Full ISO Classifications |

| Initial Cost | 40–60% Lower | Higher Upfront Investment |

| Relocation | Complete Portability | Fixed Installation |

| Expansion | Modular Additions | Requires Construction |

Why Choose Portable Cleanrooms?

When your contamination control needs to include project-based work, uncertain facility futures, or budget constraints, modular clean room systems deliver identical performance with operational advantages permanent installations cannot match. All Subzero portable systems are compatible with ISO classifications, and can be designed to support USP 797/800 requirements.

Selection Criteria for Your Application

Choosing the right portable cleanroom configuration depends on your specific operational requirements, compliance needs, and facility constraints. Consider these key factors when evaluating modular clean room options for your project.

Airflow & Filtration Configuration

- Unidirectional vs. turbulent airflow patterns

- HEPA and ULPA filtration capabilities

- Custom air change rates based on classification requirements

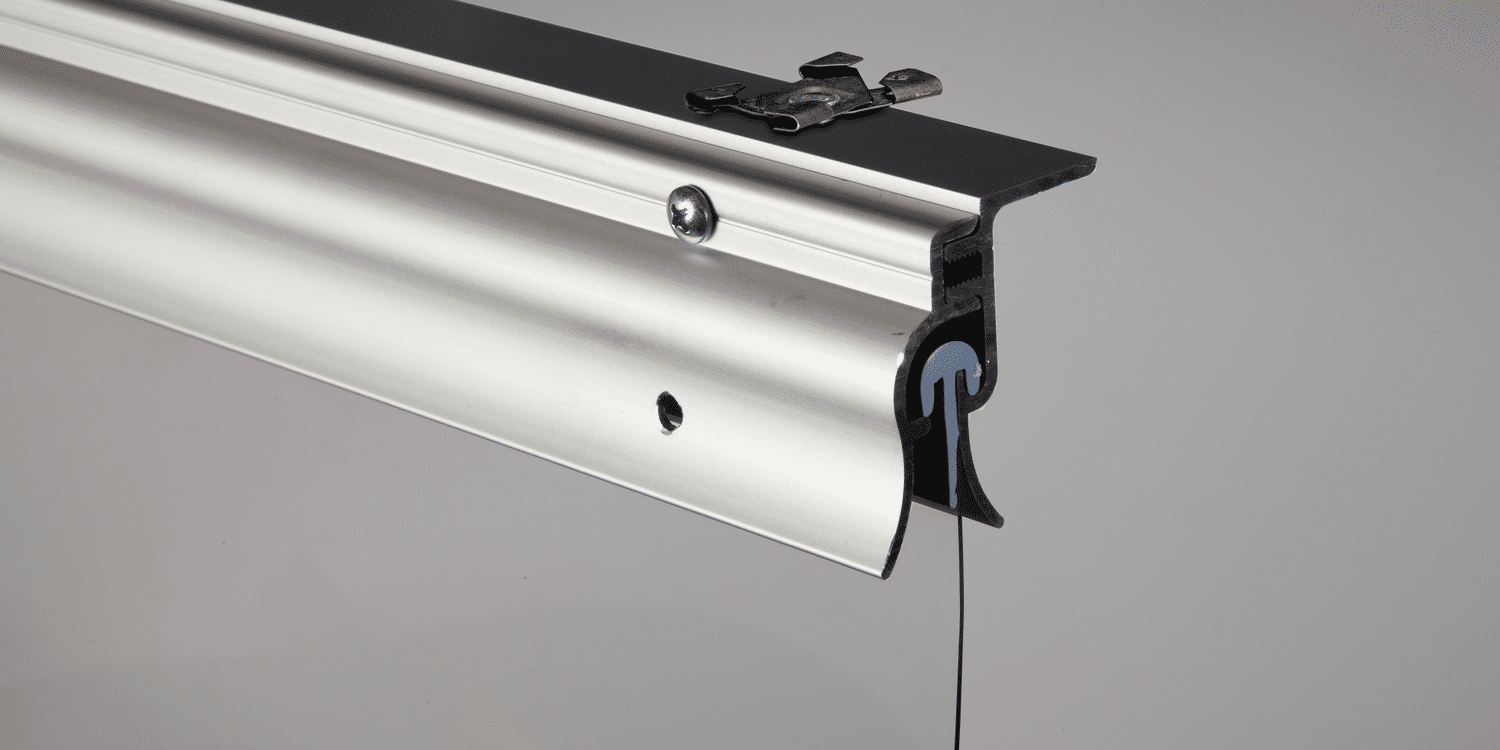

Wall System Options

- Hardwall: Maximum durability for permanent temporary installations

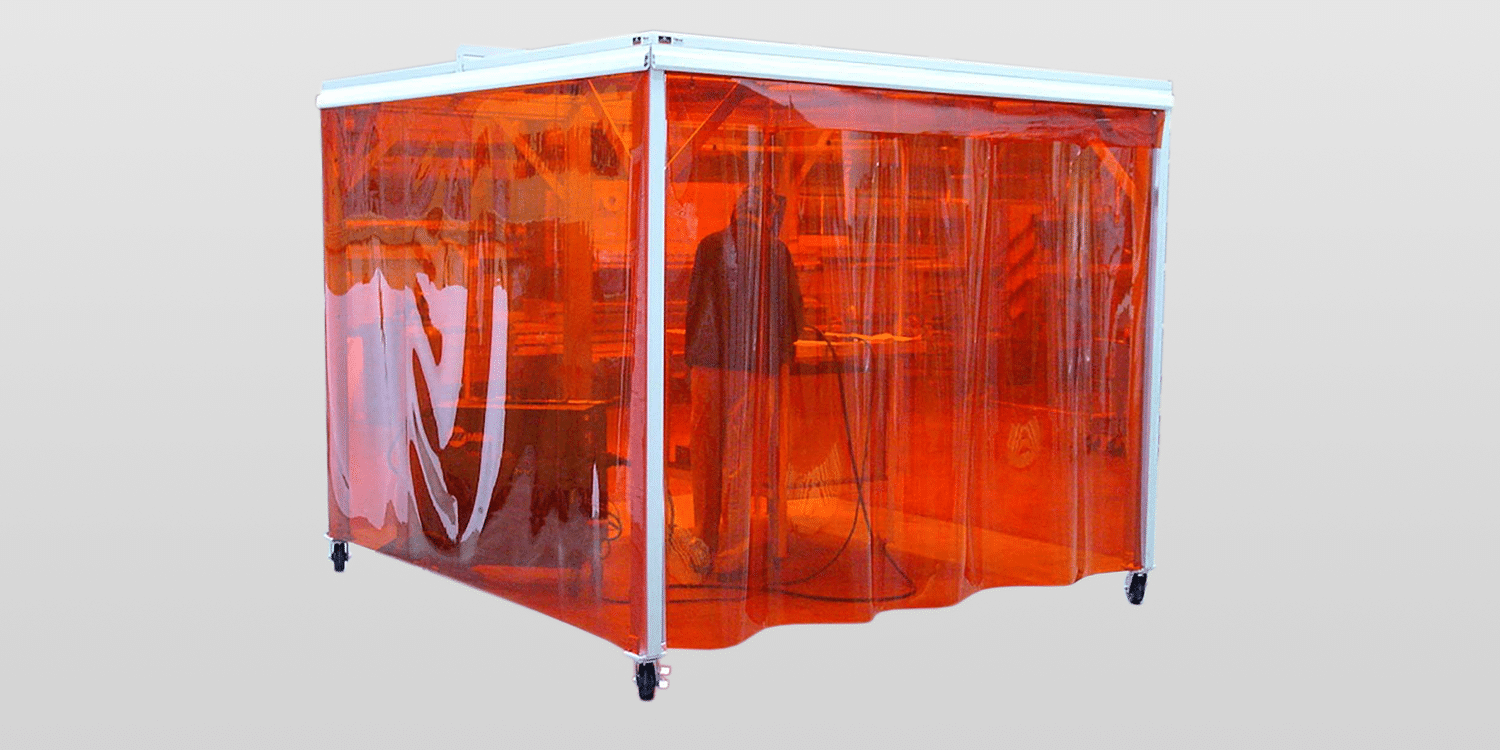

- Softwall: Ultimate flexibility for changing requirements

- Hybrid: Combining rigid framework with flexible panels

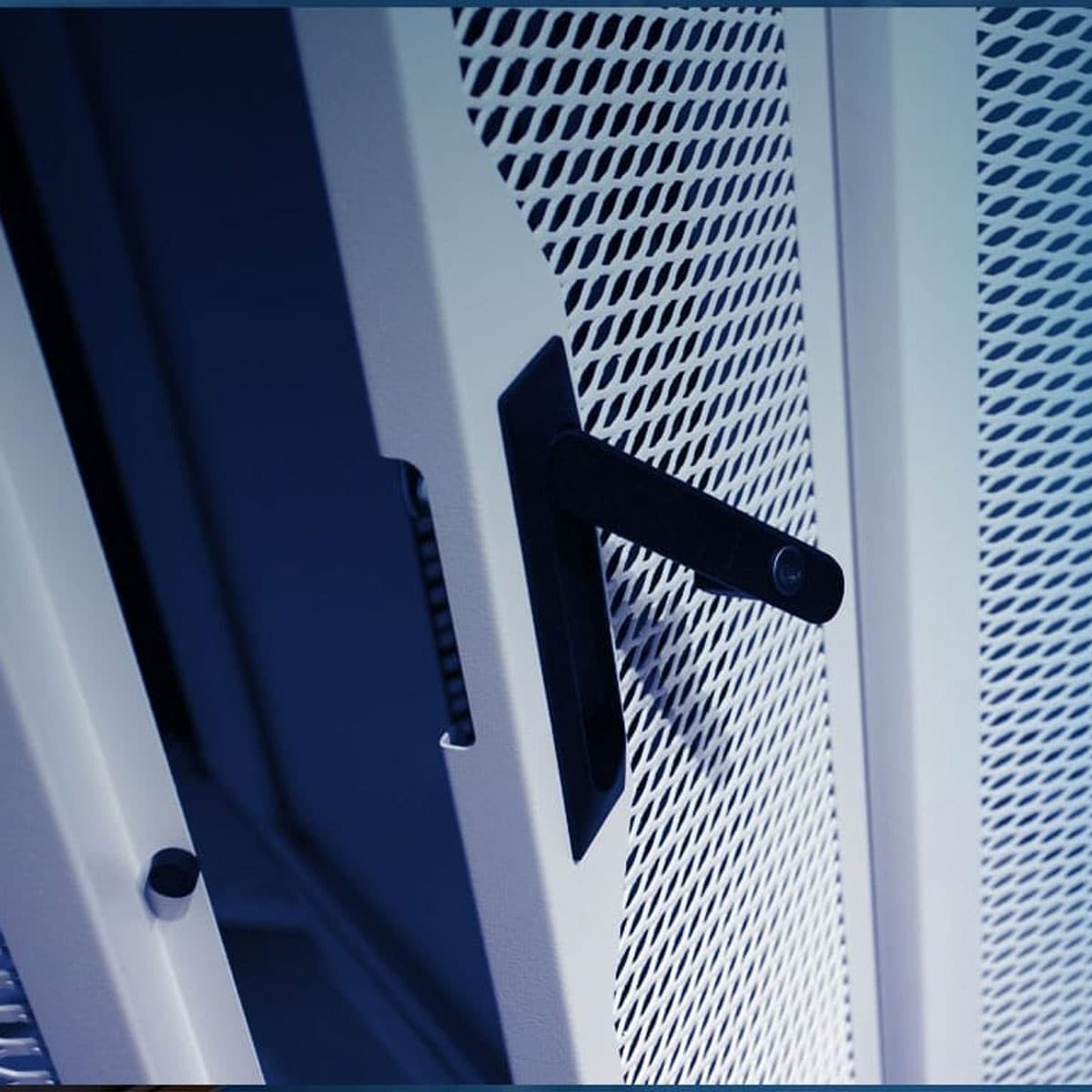

Entry and Access Systems

- Personnel entry configurations (single, dual, airlock)

- Material transfer systems and pass-throughs

- Emergency egress and safety compliance

Mobility Requirements

- Fully portable cleanrooms for complete relocation

- Semi-permanent installations with reconfiguration capability

- Modular clean room expansion options for growing operations

Size and Layout

- Standard configurations from 8×8 feet to custom dimensions

- Multi-room complexes and interconnected environments

- Ceiling height options from 8-12 feet

Compliance Specifications

- ISO 14644 classifications (Class 5-8 most common)

- USP 797 and USP 800 pharmaceutical standards

- Industry-specific regulatory requirements

Product Categories

Our comprehensive product portfolio serves critical environments across pharmaceutical, electronics, aerospace, and biotechnology industries. With thousands of successful installations worldwide, these modular clean room components have proven their reliability in the most demanding applications.

Trusted by Fortune 500 companies across pharmaceutical, electronics, and aerospace industries for critical contamination control.

Modular Clean Room Manufacturers: Why Subzero Engineering

35+ Years Combined Experience

As one of the leading prefabricated clean room manufacturers, we have engineered contamination control solutions since before modular systems became industry standard.

Proven Results

Our portable cleanroom installations achieve identical contamination control performance to permanent facilities while reducing deployment time by 75%.

Global Support

In-house manufacturing across state-of-the-art facilities with local expertise through regional partners and support teams.

Consultative Approach

We start by asking “What do you want to achieve?” rather than trying to fit existing solutions to your specific requirements.

Simplification

In 2022, a spacecraft infrastructure company received a contract to manufacture parts for the International Space Station Earth Observatory. Simplex provided fifteen separate ISO 5 cleanrooms at their manufacturing facility. Each 12′ x 12′ x 11′ cleanroom was constructed with softwall panels mounted on casters for easy portability. The modular design allowed panel frames to be disassembled and reconfigured into a larger 36′ x 60′ x 11′ room when project requirements changed.

This flexibility proved essential when production demands shifted, demonstrating exactly why portable cleanroom systems deliver operational advantages permanent installations cannot match.

Frequently Asked Questions

What is a portable cleanroom?

A portable cleanroom is a modular contamination control environment that can be quickly assembled, disassembled, and relocated. These mobile clean room systems maintain the same ISO classifications and regulatory compliance as permanent installations.

How much does a portable cleanroom cost?

Portable cleanrooms typically start around $100-150 per square foot for basic softwall configurations. A standard 10′ x 10′ portable cleanroom would range from $10,000-$15,000, representing 40-60% savings compared to permanent construction. Final pricing depends on ISO classification requirements, specialized features, and installation complexity.

What’s the difference between a clean room and sterile room?

Clean room tents and modular systems control airborne particulates to specific contamination levels (ISO classifications). Sterile rooms eliminate all viable microorganisms. Many applications require cleanroom environments rather than full sterility.

Do portable cleanrooms meet OSHA compliance requirements?

Yes. Our prefab clean rooms are engineered to meet all applicable safety and regulatory standards including OSHA requirements, fire codes, and industry-specific regulations.

What types of instant cleanroom solutions are available?

We offer hardwall, softwall, and hybrid configurations. Hardwall provides maximum durability, clean room tents offer ultimate flexibility, and hybrid systems combine rigid frameworks with flexible panels.

How easily can mobile cleanrooms be relocated?

Complete relocation typically requires 1-2 days for disassembly and 3-5 days for reassembly at the new location. All components are labeled and documented for efficient reinstallation.

Modular Clean Room Applications

Subzero Engineering’s Simplex modular clean rooms were developed with custom applications in mind. The possibilities are endless. Whatever the unique requirement, our team brings industry expertise and a proactive approach to solving even the most difficult isolation challenges.

-

Aerospace + Defense

Aerospace + Defense

We understand the complex nature of the aerospace and defense manufacturing industry.

Learn More -

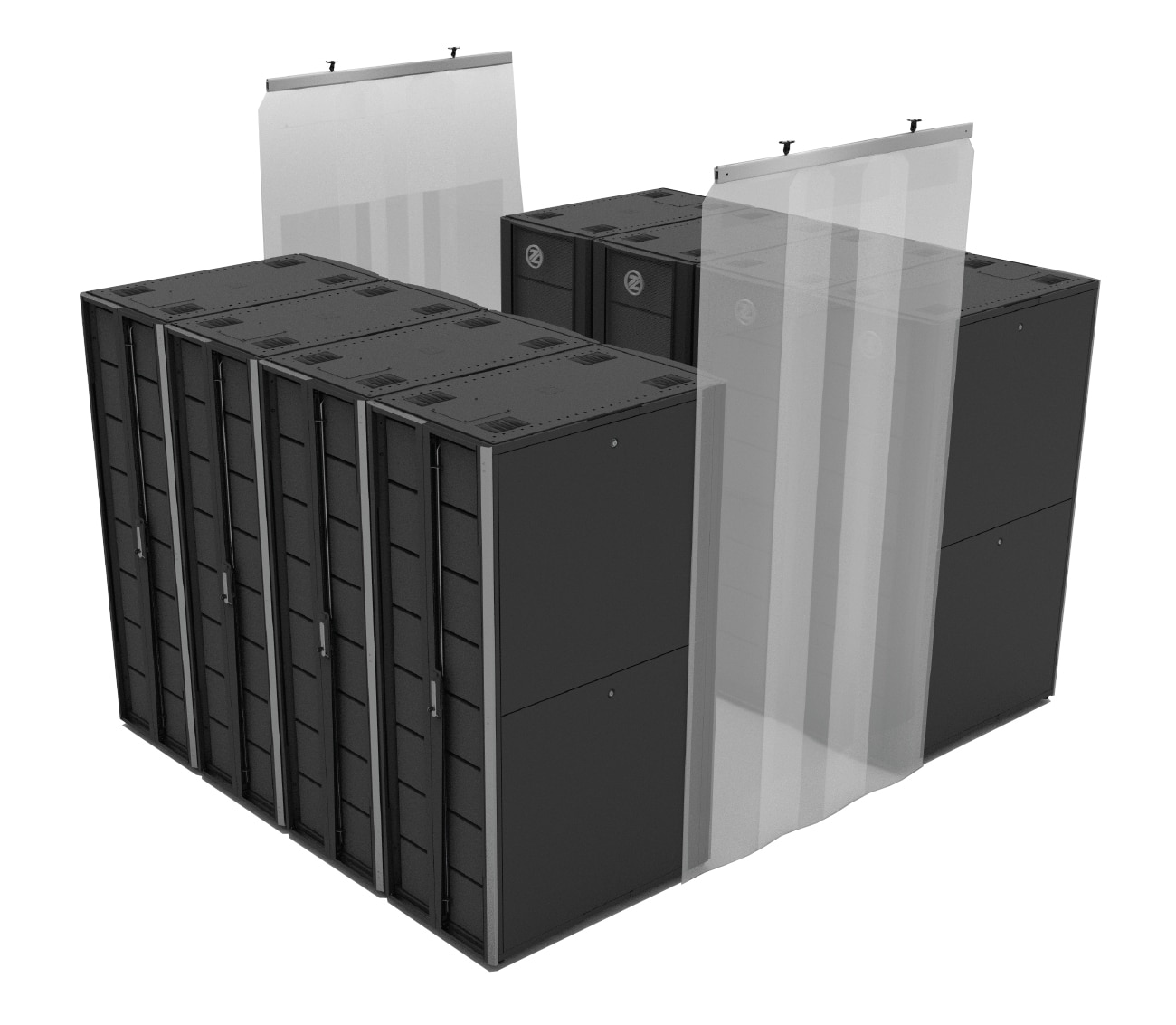

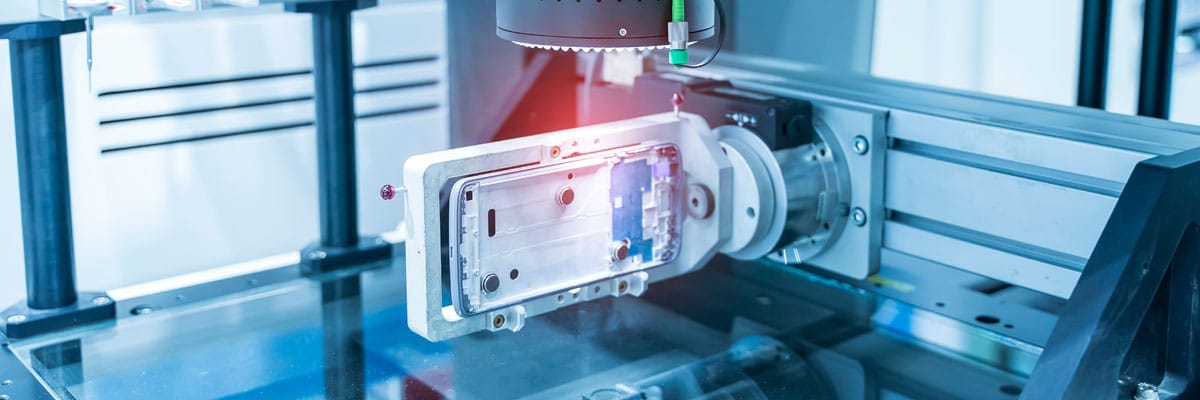

ELECTRONICS MANUFACTURING

ELECTRONICS MANUFACTURING

Modular enclosure solutions for high sensitivity electronics manufacturing environments.

Learn More -

E-LIQUID MANUFACTURING

E-LIQUID MANUFACTURING

We engineer custom e-liquid, e-cigarette, e-juice manufacturing cleanrooms compliant with current FDA regulations.

Learn More -

FOOD PREPARATION

FOOD PREPARATION

Ensure a contamination free environment to process, prep, and package food.

Learn More -

HAZMAT HANDLING

HAZMAT HANDLING

Simplex cleanrooms can be custom designed to deal with the complex handling and storage of hazardous materials.

Learn More -

LASER MANUFACTURING

LASER MANUFACTURING

Airborne contaminants can wreak havoc on lasers; Safeguard your critical laser environment.

Learn More -

Manufacturing Applications

Manufacturing Applications

Simplex cleanrooms and separation products create a variety of solutions for manufacturing facilities.

Learn More -

MEDICAL APPLICATIONS

MEDICAL APPLICATIONS

Simplex cleanrooms can be designed to efficiently Meet and Exceed Industry Regulatory Requirements.

Learn More -

PHARMECEUTICAL COMPOUNDING

PHARMECEUTICAL COMPOUNDING

We have designed numerous cleanrooms for use in the pharmaceutical industry.

Learn More -

TEMPORARY & PORTABLE

TEMPORARY & PORTABLE

Temporary/portable cleanrooms can be designed using hardwall or softwall configurations and can quickly be expanded or relocated.

Learn More